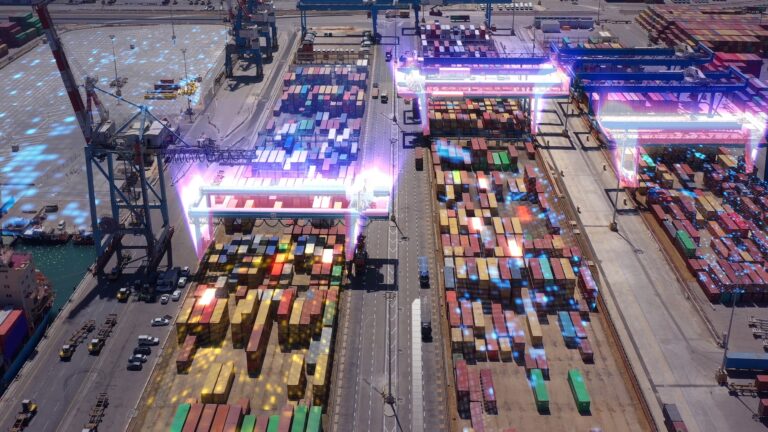

Crane, hoisting/lifting & cargo handling equipment inspections from WCS as your preferred solutions partner ensures not only cost saving benefits, but the safety & reliability of your equipment & compliance with statutory requirements.

We offer many types of inspections that are designed to satisfy your requirements & various inspections based on the manufacturer’s recommendations & our industry experience & expertise.

As one of the world’s leading companies for inspection, testing, verification & certification of all types of cranes, hoisting & lifting equipment, you can be assured of our unrivalled expertise, experience & professionalism.

Contact us today and discover more about our inspection & audit services or see the below for a summary of our services or click the Insights & News link to see areas of concern identified during some of our recent inspections.

Periodic or statutory crane inspections

Our growing team of Inspectors employed by WCS is available to provide both statutory and scheduled equipment inspections at your site to meet the demands of each respective Terminal’s operational demands.

- Annual Detailed Examinations

- 10 Year To 25 Year Statutory Thorough Inspections

- Tailored Programmes To Meet Your Local Legislative Requirements

Lifetime assessments & equipment audits

With Capital funding restrictions commonplace in the current economic climate, there is ever increasing demand for WCS to apply its unique skills to assist customers by undertaking detailed condition assessments of key assets to extract maximum use & value from existing equipment rather than replacing with new.

- Asset Valuation & Condition Assessments To Assist Capital Investment Strategy

- Ongoing Lifetime Analysis & Recommendations

- Refurbishment / Upgrade Evaluations & Proposals

- Recommendations For Ongoing Inspection Intervals

- Structural, Mechanical, & Electrical Condition Commentary

- Software Analysis & De-Bugging

- Valuation For Funding & Insurance Purposes

Finite element analysis

The assessment of aging assets that display areas of fatigue are best resolved with the aid of detailed Finite Element Models, which provide the capability to iterate different solutions in a relatively quick timescale. This approach backs up good Engineering expertise & provides our customers with graphical feedback of respective proposed solutions.

- Analysis Of Structural Failure Points

- Rapid Iteration Capacity

- Enhanced Data Presentation/ Understanding By Audience

Visual inspections

World Crane Services, in conjunction with manufacturers, suppliers & our wider Group of Companies, has adopted an engineered approach to standardize crane inspections, focusing on the structurally (or fracture) critical items, based on the experience of similar cranes. The purpose of this approach is to ensure a framework from which to establish a Structural Inspection Program regardless of crane type & integrate it into maintenance & repair regimes.

Non destructive testing inspections

Using a wide range of qualified Inspectors & NDT methods, World Crane Service can detect any cracks or material loss found on relevant Fracture Critical Member areas identified in the DP World SIM – Inspection Standards.

Non destructive testing methods include:

- VT – VISUAL TESTING

- ET – EDDY CURRENT TESTING

- MT – MAGNETIC PARTICLE TESTING

- UT – ULTRASONIC TESTING

- PT – PENETRANT TESTING

Bolt torque inspections

World Crane Service provides full Visual Bolt Inspections without dismantling any joints. Corrosion on bolts & nuts will be reviewed & as per specific request by the Client, bolts may be “tap tested” for tightness. 10% of the bolts in a joint may be checked by this means & from each joint three bolts may be selected at random for detailed examination. Should any defect be found remedial action solutions will be provided by WCS. This may include the use of Hydraulic Torque Techniques to tighten the bolt to the correct torque value.

Lifting gear inspections

World Crane Service can supply qualified Lifting Gear Inspectors to inspect any Heavy Lifting Equipment or Cargo Handling Gear. According to the Lifting Operation & Lifting Equipment Regulations, all lifting equipment should be examined & certified every 6-12 months.

Dropped object surveys

WCS can supply Dropped Object Surveyors to perform a complete inspection on various installations, platforms & cranes to identify & secure potential dropped objects i.e. floodlights, electrical power boxes, air-conditioning units, communication equipment or any equipment at heights with the potential of dropping. All equipment at height is inspected to ensure that the method of securing the equipment to the structure is appropriate & secondary retention methods can be installed to ensure double protection for certain equipment that are potential dropped objects.

Our Market Services